Solar power is a growing trend worldwide since it is readily available in most regions of the globe, and, more significantly, it is a source of renewable energy that will never run out. Although solar energy is readily available, converting it into usable energy is difficult.

However, previous research has demonstrated that it can be converted into electric energy, and current research focuses on transforming all energy absorbed into usable electric energy.

Contents

- 1 Key Takeaways

- 2 Why Is Silicon Used in Solar Cells?

- 3 Types of Photovoltaic Solar Cells

- 4 How Do Silicon Solar Cells Work?

- 5 How Much Energy Can We Get from The Sun?

- 6 What Is the Cost of A Silicon Solar Cell?

- 7 FAQs

- 8 Case Study: Residential Installation of Silicon Solar Cells

- 9 Expert Insights From Our Solar Panel Installers About Silicon Solar Cells

- 10 Discover the Power of Solar with Solar Panels Network

- 11 Summing up

Key Takeaways

- Silicon is the primary material used in solar cells due to its cost-effectiveness, high energy efficiency, photoconductivity, corrosion resistance, and natural abundance.

- There are three types of silicon-based solar cells: monocrystalline, polycrystalline, and amorphous/thin-film, each with unique characteristics influencing energy generation efficiency.

- Silicon solar cells work by adding impurities to silicon to enhance its capacity to collect and convert solar energy into electricity, harnessing the abundant and renewable energy from the Sun.

Why Is Silicon Used in Solar Cells?

Pure crystalline silicon, which has been used as an electrical component for decades, is the basic component of a conventional solar cell. Because silicon solar technology gained traction in the 1950s, silicon solar panels are called “first-generation” panels. Silicon now accounts for more than 90% of the solar cell industry.

Silicon is a cost-effective material with high energy efficiency. That is why it is frequently employed as a semiconductor material in first solar cells. Aside from that, it possesses strong photoconductivity, corrosion resistance, and long-term durability.

Because silicon is plentiful, there is practically no scarcity of raw materials for making silicon crystals.

Types of Photovoltaic Solar Cells

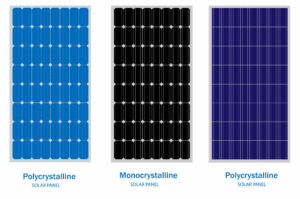

In general, silicon-based solar cells are divided into three categories based on the kind of PV cells used in them. The three types are monocrystalline, polycrystalline, and amorphous or thin-film solar cells. Each has unique characteristics that can influence the amount of electric power generated.

Monocrystalline Cells

PV cells are cut from a silicon ingot formed from pristine single-crystalline silicon cells are used to make single-crystalline cells. The cylindrical ingot’s circular curvature is squared when sliced, giving the cell its distinctive octagonal shape.

The cells are distinguished from polycrystalline silicon cells by their form. Monocrystalline solar cells also have a consistent black colour throughout. Because of the crystal’s pyramid pattern, the panel’s PV cells have a larger collection surface.

Polycrystalline Cells

PV cells cut from several silicon crystals are used to make polycrystalline cells. Silicon is melted and placed into square moulds. The silicon is sliced into squares when it has cooled in the moulds. The polycrystalline cell is distinguished from the monocrystalline cells by its perfect square form (octagonal).

These have the same qualities as monocrystalline solar panels, but they convert solar energy into electricity at a lower efficiency. Because there is less silicon waste, these cells are less expensive to produce than monocrystalline cells.

Amorphous Cells or Thin-Film Cells

Amorphous silicon solar panels are thin layers of amorphous silicon placed on a substrate. These are gaining popularity because of their mass manufacturing capabilities and their potential to be used where the surface area available for deploying the panels is not restricted.

Due to their poor efficiency, amorphous solar cells are employed in tiny applications such as pocket calculators. Layers can be merged to increase efficiency using the new ‘stacking’ approach (6-8 per cent). Because amorphous solar panels are flexible, they may also be employed on curved surfaces in novel ways.

How Do Silicon Solar Cells Work?

Because pure crystalline silicon cells are semiconductor materials at their core, they are poor conductors of electricity. To overcome this problem, impurities are added to silicon in solar cells, which means that other atoms are purposely mixed in with silicon atoms to increase silicon’s capacity to collect and convert solar energy into electricity.

Basic Operation and Performance Indicators of The Silicon Solar Cell Technology

To understand how to build high-efficiency solar panels, briefly reflecting on their key performance parameters is useful. We begin by considering the simplest form of solar cells: a semiconductor with given energy bands and conductive contacts with electrons and holes that assure charge carriers’ separation. Without a photon, photons absorbed through the cell valence band will enter the conduction band.

Gallium atoms, for example, have one fewer electron than silicon atoms, whereas arsenic atoms have one more. When arsenic atoms are sandwiched between a large number of silicon atoms, the structure will have additional electrons, resulting in an electron-rich layer.

When gallium atoms are used instead, there will be a shortage of electrons, resulting in an electron-poor layer. In a solar cell, the layers are stacked on each other, creating an electric field. When sunlight strikes solar cells, they generate electrons, leaving holes. The existence of an electric field causes them to move to the cell’s electrodes. Electrical energy is produced in this way.

How Much Energy Can We Get from The Sun?

According to the US Department of Energy, the Sun sends 430 quintillion Joules of energy to the Earth every hour. That’s 430, followed by 18 zeros! The total amount of energy consumed by all humans in a year is 410 quintillion Joules.

Therefore, the Sun gives us much more power than we need to sustain and is a brilliant renewable energy source.

What Is the Cost of A Silicon Solar Cell?

When it comes to the cost of solar cells, there are several aspects to consider. These factors include the type of solar cell placed, the system’s size, your home’s type, which direction the roof faces, and, perhaps most importantly, the quality of the panels and components (such as the inverter) utilised.

Solar cells have become considerably cheaper as the solar business has evolved and changed recently. Solar energy is a terrific form of renewable energy that will reduce your carbon footprint, independent of cost and money saved.

The cost of a typical solar spectrum, including installation, ranges from £2500 to £8000. This will vary depending on the panels you pick and the size of your roof. Solar roof tiles are far more expensive than solar panels, costing between £5000 and £14000 depending on the number required.

FAQs

What Are the Disadvantages of A Silicon Solar Cell?

The Sun’s energy is sporadic and unpredictable and can only be used in sunshine. In addition, the electricity output is diminished when the weather is overcast. Solar energy transmission over long distances is inefficient and complex. This can be a disadvantage during the winters in the UK due to the lack of sunlight.

How Efficient Are Silicon-Based Solar Cells?

The greatest silicon solar cell achieved a 26.7 per cent efficiency on a lab scale, whereas today’s standard silicon solar cell panels run at roughly 22 per cent efficiency.

As a result, many current solar research programmes are devoted to identifying and developing more effective sunlight conductors. These new organic solar cells must have a better conversion efficiency or the ability to convert a bigger proportion of incoming solar energy into electrical energy.

Case Study: Residential Installation of Silicon Solar Cells

Background

A homeowner in southern England sought a sustainable energy solution to reduce reliance on traditional power sources and lower utility bills. The property had an unshaded south-facing roof, making it ideal for solar panel installation. The homeowner chose to install a system using monocrystalline silicon solar cells, known for their high efficiency.

Project Overview

The goal was to install a solar panel system capable of covering a significant portion of the household’s electricity consumption, thus reducing monthly energy expenses and contributing excess power to the grid through the Smart Export Guarantee (SEG).

Implementation

- System Design and Selection: After a thorough site assessment, a 4kW solar system was selected, consisting of 16 monocrystalline silicon panels, each rated at 250 watts. The panels were chosen for their high efficiency and durability.

- Installation: The installation was carried out by an MCS-certified installer, ensuring eligibility for SEG payments. The panels were mounted on the roof using a racking system that allowed optimal angle adjustment for maximum solar exposure.

- Grid Connection and SEG Enrollment: The system was connected to the national grid, and the homeowner registered for the SEG program, allowing them to sell excess electricity generated by the solar panels.

Results

- Energy Production: The system produced approximately 4,400 kWh annually, covering around 70% of the household’s electricity needs.

- Financial Benefits: The homeowner saved an estimated £500 annually on energy bills. Additionally, the SEG provided approximately £200 per year from exporting excess energy to the grid.

- Environmental Impact: The solar installation reduced the household’s carbon footprint by about 1.5 tonnes of CO2 annually, contributing to a cleaner environment.

Summary

The installation of silicon-based solar cells provided the homeowner with significant financial savings and reduced their environmental impact. The system’s high efficiency and the ability to export surplus electricity made it a valuable investment, highlighting the potential benefits of adopting solar technology in residential settings.

Expert Insights From Our Solar Panel Installers About Silicon Solar Cells

Silicon has remained the material of choice for solar cells due to its abundance, durability, and efficiency. Its properties make it an excellent semiconductor, allowing for effective conversion of sunlight into electricity.

Chief Solar Engineer

Monocrystalline silicon solar cells offer the highest efficiency among silicon-based options, typically achieving 22% efficiency in commercial panels. This makes them a preferred choice for installations where space is limited.

Renewable Energy Specialist

One of the main challenges with silicon solar cells is the energy-intensive process of producing high-purity silicon. However, advances in manufacturing techniques continue to lower costs and improve accessibility.

Solar Technology Analyst

Discover the Power of Solar with Solar Panels Network

Are you navigating the world of solar installations? Look no further than Solar Panels Network, the UK’s trusted partner in harnessing the Sun’s potential. Our dedication goes beyond just installations; we’re on a mission to transform how homeowners and businesses across the UK perceive and utilise energy. By choosing us, you’re reducing your carbon footprint and making a smart financial move that promises savings for years ahead. Contact us today and embark on your solar journey.

Summing up

Solar cells are brilliant renewable energy sources and can provide more power than the entire human race needs. As the planet stands on the brink of climate change and extinction rebellion, with governments racing toward renewable energy, we can do our part to save the climate.

Solar cells are also budget-friendly, with no hefty electricity bill required. It would be best to try solar cells to light up your house to reduce your carbon footprint.

About the Author

Solar Panels Network stands at the forefront of solar energy solutions, driven by a team of seasoned solar engineers and energy consultants. With over decades of experience in delivering high-quality solar installations and maintenance, we are committed to promoting sustainable energy through customer-centric, tailored solutions. Our articles reflect this commitment, crafted collaboratively by experts to provide accurate, up-to-date insights into solar technology, ensuring our readers are well-informed and empowered in their solar energy decisions.